“That’s why we only buy from responsible raw material suppliers who, through their manufacturing process, are reducing the carbon footprint of the entire value chain. In addition, we have developed our manufacturing process to be more efficient. For example, we have reduced the amount of scrap generated from production by 42% during the past four years”, explains EQHS & Sustainability Engineer Tanja Pakarinen.

EQHS & Sustainability Engineer Tanja Pakarinen & EQHS Manager Teppo Lassila

Life cycle assessment study (LCA)

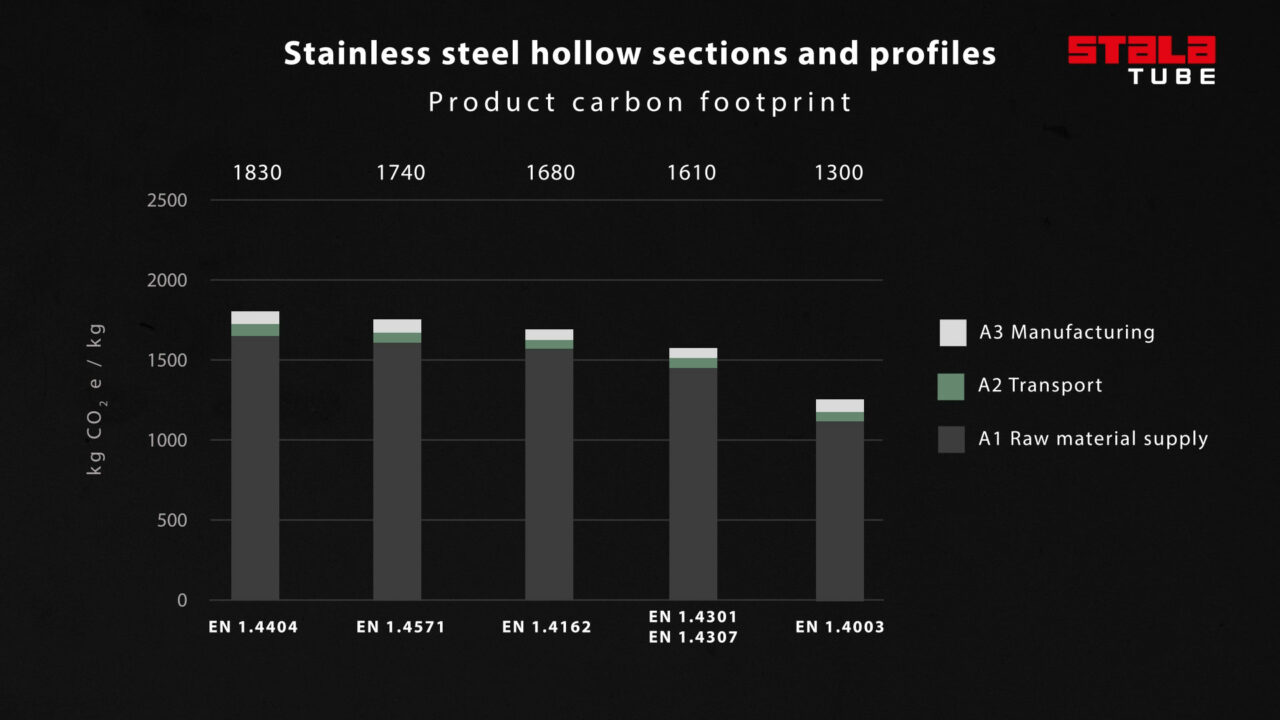

Stalatube has carried out a Life-Cycle Assessment study as a basis for five Environmental Product Declarations (EPD), complying with ISO 14040:2006 + A1:2020, EN ISO 14044:2006 + A1:2018 +A2:2020, EN 15804:2012 + A2:2019, and PCR for Construction products v.1.3.1. The report aims to provide customers with reliable and comparable information on the environmental impact of Stalatube’s products. The objective of the LCA study is to understand where in the life cycle of the products the environmental burden lay, to highlight where actions to reduce the environmental burden should be taken, and to illustrate where in the life cycle the environmental hot spots are most significant. Additionally, the results are compiled to produce an EPD.

As one of the first stainless steel hollow section manufacturer, Stalatube has launched Environmental Product Declarations for stainless steel hollow sections. The declarations are ready for the following hollow section grades and are published at www.stalatube.com :

- Stainless steel hollow sections and profiles Grade EN 1.4301/1.4307

- Stainless steel hollow sections and profiles Grade EN 1.4003

- Stainless steel hollow sections and profiles Grade EN 1.4404

- Stainless steel hollow sections and profiles Grade EN 1.4571

- Stainless steel hollow sections and profiles Grade EN 1.4162

From cradle to gate

The declared unit used in the study is one tonne (1,000 kg) of steel product. No functional unit is defined as the assessment boundary was set to ‘cradle-to-gate with options’. The assessment covers the product stage (A1-A3) which means that the study covers raw material manufacturing and transport and manufacturing of the final product.

“The more precisely we can calculate, the better results we seem to get. At the same time, our customers benefit from our data on their emission calculations. The more accurate our data is, the better for the customers as well”, states Stalatube’s EQHS Manager Teppo Lassila.

The steel hollow sections and profiles are manufactured at Stalatube’s production plant in Lahti, Finland. The manufacturing process consists of the following phases: cold roll forming, welding, and cutting to length followed by optional surface treatments such as polishing or pickling and passivation.

“In my understanding, we are now the first stainless steel hollow section manufacturer that has published environmental product declarations so far. We are therefore at the forefront of emission reporting in our field”, says Teppo.

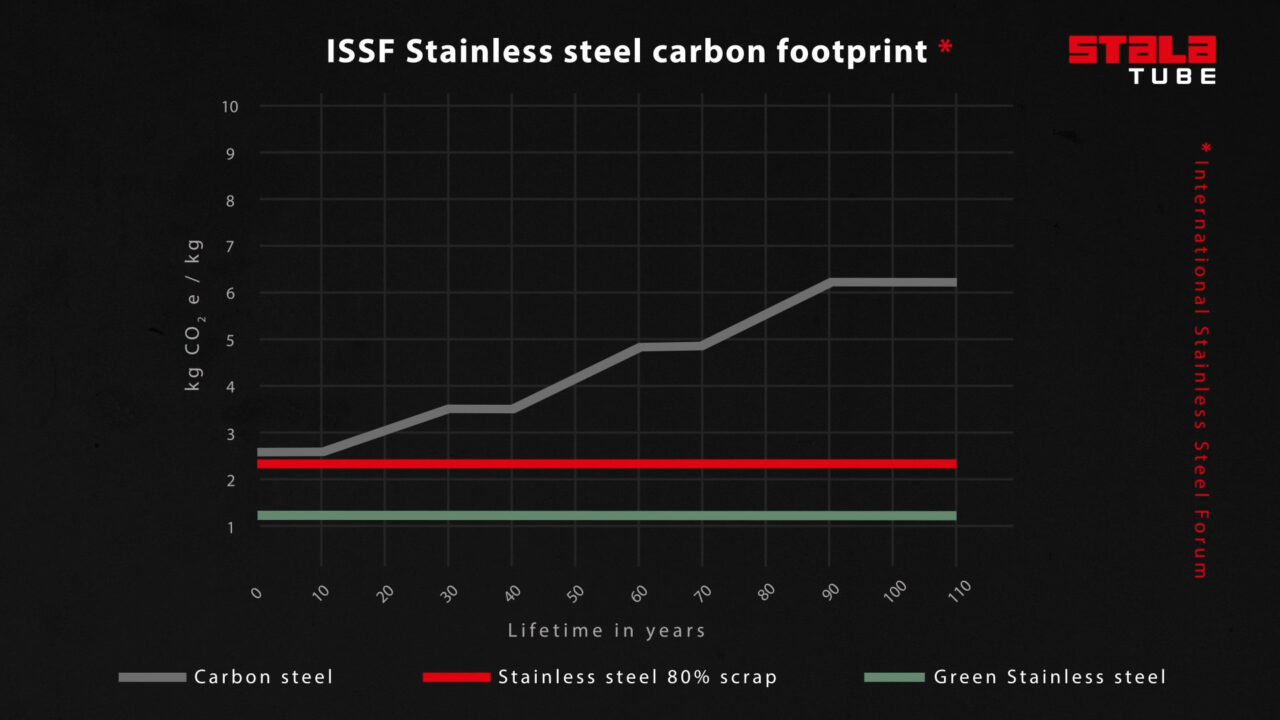

Carbon steel versus stainless steel

Some of the carbon steel pipe manufacturers have published their product declarations. As a comparison, commonly carbon steel pipe has higher emission values, even without calculating carbon steel’s maintenance costs in the long run. As a result, all our stainless steel hollow sections emission factors are under 2.0 as illustrated in the animation below.

Valuable information is always verified by official third-party

How to get responsible and up-to-date emission information about different products? How to compare?

Although the main goal of EPD is to become transparent and provide our customers with proven data that allows them to influence the emission values of their products accordingly, people need EPD reading skills.

“You need to understand what is included in the calculations and what is not. And also, be able to focus on those emission sources, which have the greatest influence on the total emission. The official third party is needed to maintain impartiality and the same rules”, explains Teppo.

Verified Environmental Product Declarations are published and downloaded from the International EPD system’s EPD library (htt. Information in the EPDs is comparable to each other and the declarations are an essential source of information when calculating e.g. carbon footprint of buildings and other structures.

Carbon reporting is heating up

Stalatube is on its way to net zero carbon emissions by 2030. Meeting the recent sustainability and climate change requirements of the EU directives can cause headaches for some of the companies that have not previously had a reporting obligation. In addition, the company’s emissions lead to increasing costs because emission credits need to be traded or emissions have to be compensated.

“However, we at Stalatube believe that low-emission products are the most desirable as long as they become to the same level in terms of cost. And the price difference becomes smaller and smaller every year. Because of legislation or market forces, the extremities converge”, forecasts both Tanja and Teppo.

Teppo Lassila

EQHS Manager IWE & IWI-CStalatube Oy (Finland)

Technical support