Practical measures to improve the energy efficiency of production and buildings have been systematically implemented. Between 2021 and 2023, a number of changes have been made to improve energy efficiency:

- 3 water-to-air pumps were as heat sources

- The automation of the ventilation and heating control of the whole building was renewed, which allows for example intelligent control of the ventilation, using run-time data of the production lines

- Door curtain fans were installed on the large lifting doors of the factory building

- Lighting in the factory and outdoor areas was replaced with LED-technology

With the runtime data from the production lines, the ventilation can be adjusted to work exactly when the ventilation is needed. This was not possible with the old automation, so the change has had a huge impact on electricity demand in particular, comments Kimmo Myyrä, Operations Manager.

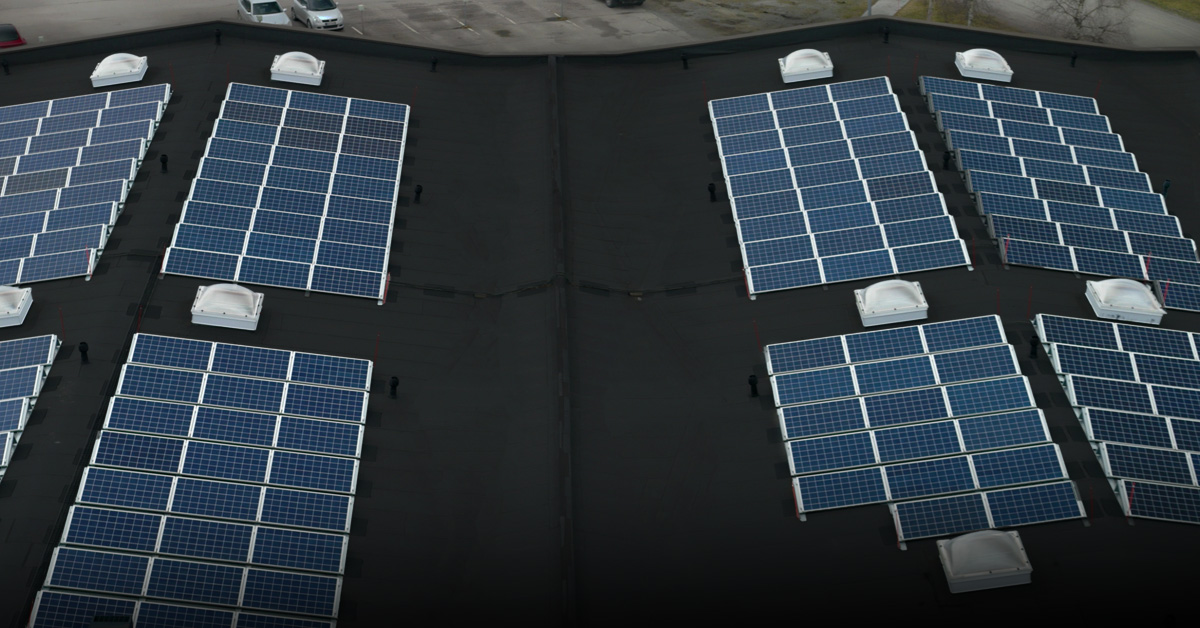

The accomplished savings are significant. The annual demand for district heat has dropped by around 1000 MWh, a staggering 40%, while the annual demand for electricity has dropped by over 1300 MWh, a reduction of around 24%. This means in total annual cost savings of more than €200,000. Measures to improve energy efficiency in the near future include phasing out of internal combustion engine forklifts and a switch to electric forklifts, which will save around 25 000 litres of fuel per year, and an increase in solar energy capacity during 2024.

During this year, there will be a further focus on improving the filtration of welding gases from the production lines. The ventilation ducts in the lines will be shortened and the duct diameters will be significantly reduced. These changes will allow the heat generated from production to be recycled in the factory hall, even further reducing the need for district heating and significantly reducing energy efficiency, says Myyrä, explaining the near future plans for energy efficiency improvements.