High-strength stainless steel, particularly lean duplex (LDX) varieties, significantly contributes to meeting sustainability and ESG (Environmental, Social, and Governance) goals. By providing superior strength-to-weight ratios, these advanced materials enable substantial material reduction in structural applications—decreasing resource consumption, lowering carbon footprints, and reducing transportation emissions. Additionally, their exceptional durability, corrosion resistance, and 100% recyclability support circular economy principles, making high-strength stainless steel an environmentally responsible choice for construction and manufacturing projects focused on long-term sustainability.

Understanding high-strength stainless steel and sustainability challenges

High-strength stainless steel represents a significant advancement in sustainable construction materials. These specialised alloys, particularly lean duplex stainless steel (LDX), deliver exceptional mechanical properties whilst requiring less material than conventional options. With yield strengths significantly higher than traditional austenitic stainless steels, grades like EN 1.4062 and EN 1.4162 enable lighter, more efficient structures.

Today’s construction and manufacturing industries face mounting pressure to reduce environmental impacts whilst maintaining structural integrity and safety. Regulatory requirements, investor expectations, and consumer demand increasingly prioritise sustainable practices and materials that support ESG frameworks.

The challenge lies in finding materials that balance structural performance with environmental responsibility. High-strength stainless solutions from Stalatube, including our enhanced strength classes like Stala350, Stala400F, and Stala630D, directly address this challenge by providing superior mechanical properties with reduced material usage—fundamentally changing how sustainable structures can be designed and built.

How does high-strength stainless steel reduce environmental impact?

High-strength stainless steel reduces environmental impact primarily through its exceptional strength-to-weight ratio, allowing for significant material reduction whilst maintaining structural performance. By using lean duplex stainless steel, engineers can design structures with up to 30% less material compared to conventional stainless options.

This material efficiency creates cascading environmental benefits throughout the product lifecycle:

- Lower raw material consumption preserves natural resources

- Reduced energy requirements during manufacturing

- Decreased transport emissions due to lighter components

- Smaller carbon footprint across the entire supply chain

The environmental advantages become particularly evident in large-scale applications. For instance, when used in building frameworks, transportation infrastructure, or industrial equipment, high-strength stainless steel’s material efficiency translates into measurable reductions in embodied carbon and resource consumption, supporting key environmental sustainability metrics within ESG reporting frameworks.

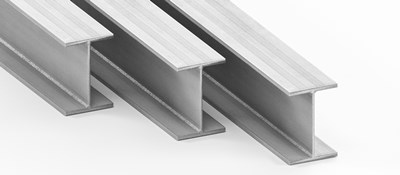

What makes stainless steel hollow sections more sustainable than other structural options?

Stainless steel hollow sections offer unique sustainability advantages through their optimised geometric design and material properties. Their closed shape provides uniform strength distribution across all axes under compressive loads, allowing them to support substantial weights whilst using minimal material.

This structural efficiency delivers several sustainability benefits:

- Superior stability with less material compared to open profiles

- Ability to support large loads whilst maintaining relatively low weight

- Reduced foundation requirements due to lighter overall structures

- Lower total material consumption throughout the building system

At Stalatube, our high-strength hollow sections maximise these advantages through enhanced mechanical properties. Our roll-formed and press-braked tubes create structurally efficient profiles that maintain stability with significantly less material than alternative structural systems, supporting sustainability goals through fundamental resource efficiency.

How does the longevity of high-strength stainless steel contribute to ESG goals?

The exceptional longevity of high-strength stainless steel directly supports ESG goals by dramatically extending service life and eliminating the environmental impacts associated with maintenance and replacement. With superior corrosion resistance even in aggressive environments, these materials often provide service lifespans measured in decades rather than years.

This durability creates multiple ESG benefits:

- Reduced maintenance requirements eliminate chemicals, energy, and resources needed for upkeep

- Fewer replacement cycles decrease lifetime material consumption and waste generation

- Lower lifecycle environmental impact compared to materials requiring regular replacement

- Improved safety and reliability supports social responsibility aspects of ESG

By avoiding the resource-intensive cycle of replacement and maintenance, high-strength stainless steel structures effectively spread their initial environmental impact across decades of service, substantially lowering their annualised environmental footprint. This longevity factor is increasingly recognised in ESG assessment frameworks as a critical component of truly sustainable infrastructure.

What role does recyclability play in stainless steel’s sustainability profile?

Recyclability forms a cornerstone of stainless steel’s sustainability credentials, with the material being 100% recyclable without degradation of properties through multiple life cycles. Unlike many materials that downcycle, stainless steel can be continuously reprocessed into new high-performance products of identical quality.

This circularity delivers significant environmental benefits:

- Conservation of natural resources through continuous material reuse

- Reduced energy consumption compared to primary production

- Lower overall carbon emissions across the material lifecycle

- High end-of-life value that incentivises responsible disposal and recovery

At Stalatube, our stainless steel products contain a high percentage of recycled content, further enhancing their sustainability profile. This closed-loop approach to material usage supports circular economy principles, addressing both environmental aspects and governance components of ESG frameworks by promoting responsible resource management.

High-strength stainless steel as a cornerstone of sustainable construction

High-strength stainless steel delivers multiple sustainability advantages that position it as an essential material for ESG-focused projects. By enabling substantial weight reduction whilst maintaining structural integrity, these advanced materials support modern sustainability frameworks through fundamental resource efficiency and environmental responsibility.

The comprehensive sustainability benefits include:

- Material reduction of up to 30% through superior strength-to-weight ratios

- Exceptional durability that eliminates maintenance and extends service life

- Complete recyclability that supports circular economy principles

- Structural efficiency that minimises resource consumption throughout building systems

As providers of high-strength stainless steel solutions, Stalatube offers products specifically engineered to maximise these sustainability advantages. Our lean duplex stainless steel and enhanced strength classes enable designers and engineers to achieve ESG objectives without compromising on performance, helping organisations build more sustainably whilst meeting increasingly stringent environmental requirements.

This article was created with the help of AI and reviewed by a human. It may include mistakes.