Understanding dynamic loads in structural applications

High-strength stainless steel demonstrates exceptional performance under dynamic loads due to its superior mechanical properties and structural integrity. When subjected to forces that change in magnitude, direction, or point of application over time, high-strength stainless steel hollow sections maintain remarkable stability while absorbing and distributing these forces effectively. Materials like lean duplex (LDX) stainless steel offer an optimal combination of yield strength, tensile strength, and fatigue resistance that significantly outperforms standard grades when handling cyclic loads, impact forces, and vibrations. This performance translates to enhanced structural safety, longer service life, and reduced maintenance requirements in demanding applications.

Understanding dynamic loads in structural applications

Dynamic loads are forces that change in magnitude, direction, or point of application over time, contrasting with static loads which remain constant. Structural applications regularly face three main types of dynamic loads: cyclic loads (repetitive forces like those in machinery), impact loads (sudden forces from collisions), and vibration loads (oscillating forces from environmental factors or equipment).

Unlike static loads, dynamic forces introduce complexity through factors such as acceleration, velocity, and the structure’s natural frequency. This makes material selection particularly critical, as materials must possess specific properties to absorb, distribute, and resist these changing forces without premature failure.

Traditional materials often struggle with fatigue and stress concentration under dynamic conditions. High-strength stainless steel, with its superior ductility and strain-hardening capabilities, provides an ideal solution for structures subject to variable forces. The material’s ability to absorb energy while maintaining structural integrity makes it particularly valuable in applications where dynamic loads are common and failure is not an option.

What makes high-strength stainless steel ideal for dynamic load applications?

High-strength stainless steel excels under dynamic loads due to its exceptional mechanical properties that combine strength with necessary flexibility. The superior yield and tensile strength of these materials—particularly lean duplex (LDX) grades with yield strengths exceeding 630 MPa—enable structures to withstand significant force without permanent deformation, a critical factor when loads continually change.

Beyond pure strength, high-strength stainless steel offers remarkable elongation properties, typically maintaining minimum elongation of 20% even in high-strength variants. This ductility allows the material to absorb energy from dynamic impacts or vibrations rather than transferring it directly through the structure, preventing premature fatigue failure and structural damage.

The material’s fatigue resistance is particularly valuable in dynamic applications. High-strength stainless steel maintains its mechanical properties even after millions of load cycles, significantly outperforming traditional materials in structures subjected to repeated stress. This fatigue resistance, combined with inherent corrosion resistance, ensures long-term reliability in dynamic environments where structural integrity cannot be compromised.

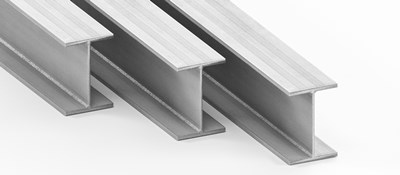

How do stainless steel hollow sections distribute dynamic forces?

Stainless steel hollow sections excel at distributing dynamic forces due to their geometrically efficient design. Square and rectangular sections provide uniform strength across all axes, creating a balanced response to multi-directional dynamic loads that might otherwise cause structural failure through uneven stress distribution.

The closed profile of hollow sections offers superior torsional rigidity compared to open sections, making them particularly effective at resisting twisting forces often present in dynamic loading scenarios. This resistance to torsion is crucial for maintaining structural stability when forces come from varying directions or create complex stress patterns within the material.

The inherent stiffness-to-weight ratio of stainless steel hollow sections also contributes to their dynamic performance by minimising deflection under load. By limiting movement and maintaining shape under variable forces, these sections prevent the amplification of dynamic loads that occurs when structures resonate with applied forces. This ability to control deflection becomes particularly valuable in applications where precision and dimensional stability must be maintained despite changing loads.

What role does manufacturing process play in dynamic load performance?

The manufacturing process significantly influences how high-strength stainless steel performs under dynamic loads. Stalatube’s roll forming and press braking techniques create hollow sections with consistent mechanical properties throughout the material, eliminating weak points that could become failure initiation sites under cyclical loading conditions.

Roll forming preserves the material’s grain structure, maintaining the inherent strength and ductility of the high-strength stainless steel. This consistency is crucial for dynamic load applications, as it ensures the predictable distribution of forces throughout the structure and prevents premature failure due to manufacturing inconsistencies.

Precise corner formation during manufacturing prevents stress concentration that would otherwise create vulnerability under dynamic loads. By maintaining uniform material thickness around corners and ensuring clean, consistent welding, our manufacturing processes create hollow sections that distribute dynamic forces evenly, significantly enhancing fatigue resistance and long-term structural integrity under variable loading conditions.

How does weight-to-strength ratio impact dynamic load behavior?

The exceptional weight-to-strength ratio of high-strength stainless steel dramatically influences dynamic load behavior by reducing inertial forces within structures. With strengths permitting up to 50% thinner wall thickness compared to standard materials, our high-strength hollow sections support large loads while significantly reducing the structure’s mass. This reduced structural weight means less inertia during dynamic events, resulting in lower overall force amplification during acceleration or deceleration.

Lighter structures respond more efficiently to dynamic loads by reducing the natural amplification that occurs due to the structure’s own mass. This is particularly important in applications involving rapid movement, vibration, or seismic activity, where the structure’s weight can significantly increase the total forces the material must withstand.

The optimized weight-to-strength ratio also allows for greater design flexibility in dynamic load applications. Engineers can either create lighter structures with the same load-bearing capacity or maintain weight while significantly increasing performance margins. This flexibility is valuable in applications where both weight and dynamic load management are critical design considerations.

Key takeaways on high-strength stainless steel performance

High-strength stainless steel hollow sections offer superior durability and stability under dynamic loads compared to conventional materials. Their unique combination of high yield strength, tensile strength, and exceptional elongation properties enables them to absorb, distribute, and resist variable forces more effectively, significantly extending structural lifespan in demanding applications.

The weight savings achieved through high-strength stainless steel—up to 50% thinner walls without compromising functionality—translate directly to improved dynamic performance by reducing inertial forces and natural frequency issues. These savings also contribute to sustainability through reduced material use, lower transportation emissions, and complete recyclability at end of life.

Our expertise in high-strength stainless steel solutions, particularly lean duplex grades like STALA630D, enables us to provide optimal materials for the most demanding dynamic load applications. With over 50 years of experience and one of the largest ranges of stainless steel hollow sections and profiles, we deliver the right combination of strength, stability, and performance for structures that must withstand the challenges of dynamic loading conditions reliably and efficiently.

This article was created with the help of AI and reviewed by a human. It may include mistakes.