Understanding high-strength stainless steel’s unique properties for frame design

High-strength stainless steel offers exceptional design flexibility for frames through its unique combination of mechanical properties and structural characteristics. By utilizing materials like lean duplex stainless steel (LDX), designers can create frames with significantly thinner wall thicknesses while maintaining—and often improving—structural stability and load-bearing capacity. This enables more elegant, minimalist structures with longer spans and reduced material requirements. The superior strength-to-weight ratio of high-strength stainless steel hollow sections allows for up to 40% weight reduction compared to conventional materials, opening new possibilities in architectural design while enhancing sustainability through reduced material consumption and lower transportation costs.

Understanding high-strength stainless steel’s unique properties for frame design

High-strength stainless steel represents a significant advancement in structural material technology, offering designers an expanded palette of possibilities that traditional materials cannot match. At the core of this versatility is the exceptional yield strength of high-strength stainless steel grades like lean duplex (LDX), which dramatically outperforms conventional stainless steel options.

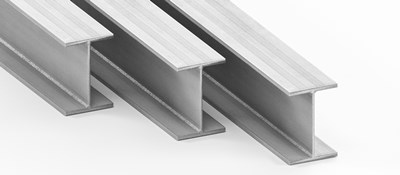

These advanced materials combine corrosion resistance with mechanical properties that allow for remarkable design flexibility. The higher yield and tensile strength enables engineers to specify smaller wall thicknesses while maintaining the same outer dimensions of structural elements, creating visually identical components that perform equally well or better than their thicker-walled counterparts.

Our high-strength stainless steel hollow sections deliver uniform strength across all axes, providing significant advantages under compressive load scenarios. This consistent performance across different stress directions allows designers to create more streamlined, efficient structures that would be impossible with conventional materials.

The inherent durability of high-strength stainless steel also contributes to design flexibility by eliminating the need for protective coatings or substantial safety margins that might otherwise compromise aesthetic goals. This combination of properties allows architects and engineers to push the boundaries of what’s structurally possible while maintaining the elegant, clean lines that modern design demands.

How does high-strength stainless steel improve frame weight-to-strength ratios?

High-strength stainless steel delivers remarkable improvements in frame weight-to-strength ratios through its superior mechanical properties. This translates directly into substantial weight savings without compromising structural integrity or safety requirements.

The exceptional strength characteristics of our high-strength stainless steel allow for wall thickness reductions of up to 50% compared to standard stainless steel grades. For example, a 100x100x6 mm standard stainless steel hollow section can often be replaced with a 100x100x3 mm high-strength alternative while maintaining equivalent strength performance in many load scenarios.

Our square tubes provide uniform strength across all axes, making them exceptionally efficient for carrying compressive loads. This uniform strength distribution is particularly valuable in frame designs, where forces can come from multiple directions and structural predictability is essential.

The weight reduction benefits extend beyond just the frame itself. Lighter structures require less substantial foundations, reduced lifting equipment capacity during installation, and lower transportation costs. This cascading effect of weight savings creates a multiplier effect on the overall efficiency of projects utilizing high-strength stainless steel frames.

By maintaining outer dimensions while reducing wall thickness, high-strength stainless steel hollow sections preserve the same bending resistance and structural stability as standard materials but at a fraction of the weight. This perfect balance of strength and lightness opens new possibilities for designers working within strict weight constraints.

What architectural design possibilities can high-strength stainless steel frames unlock?

High-strength stainless steel frames unlock extraordinary architectural possibilities that would be structurally impossible or economically unfeasible with conventional materials. The exceptional strength-to-weight ratio enables the creation of more minimalist structures with longer spans and reduced visible support elements.

Architects can now design expansive glass walls and impressive cantilevered features with fewer visible structural supports. The reduced material requirements don’t just save weight—they transform the visual language of buildings by allowing greater transparency and openness in designs that would otherwise require more substantial framing elements.

Our high-strength stainless steel hollow sections provide the structural backbone for dramatic architectural statements in applications ranging from grand public spaces to striking residential designs. The clean lines and material efficiency possible with these advanced materials align perfectly with contemporary architectural trends emphasizing minimalism and visual lightness.

Beyond aesthetic considerations, high-strength stainless steel frames offer practical advantages in challenging environments. Their inherent corrosion resistance makes them ideal for coastal buildings, aquatic centres, and other applications exposed to harsh conditions. This durability ensures that ambitious architectural visions remain structurally sound and visually pristine for decades, even in demanding settings.

The superior load distribution characteristics of square and rectangular hollow sections also allow for more creative structural arrangements, giving architects greater freedom to explore innovative forms while maintaining essential structural stability.

How are high-strength stainless steel frames manufactured for maximum design flexibility?

High-strength stainless steel frames achieve maximum design flexibility through sophisticated manufacturing processes that enhance both material properties and dimensional precision. Our roll forming and press braking techniques allow us to create hollow sections and profiles that meet exacting specifications for diverse architectural and structural applications.

Roll forming represents one of our primary manufacturing methods, enabling the continuous production of consistent, high-quality structural elements. This process allows for tight dimensional tolerances and excellent surface finishes, both crucial factors in applications where aesthetics are as important as structural performance.

Press braking complements our manufacturing capabilities by allowing the creation of more complex profiles and custom components that might not be achievable through standard roll forming alone. This versatility in forming methods enables us to respond to unique design requirements with tailored solutions.

The enhanced strength classes we offer, such as STALA500 and STALA630D, are achieved through precise control of both chemical composition and processing parameters. This meticulous approach to manufacturing ensures that our high-strength stainless steel products deliver consistent performance that designers can rely on.

Our manufacturing flexibility extends to a wide range of dimensions and specifications, allowing architects and engineers to select the exact profiles needed for their projects rather than compromising designs to accommodate standard sizes. This manufacturing adaptability translates directly into greater design freedom.

What sustainability benefits do high-strength stainless steel frames offer in modern design?

High-strength stainless steel frames deliver exceptional sustainability benefits that align perfectly with modern environmental design principles. The material efficiency achieved through reduced wall thickness directly translates to significant resource conservation, with material usage reductions of 25-35% being typical, and savings of over 40% possible in optimised applications.

This material reduction cascades throughout the entire supply chain, reducing environmental impacts from mining and processing raw materials to transportation and manufacturing energy consumption. Every kilogram of steel saved represents a substantial reduction in embodied carbon and resource depletion.

Stainless steel’s inherent longevity and 100% recyclability further enhance its sustainability credentials. High-strength stainless steel frames typically maintain their structural integrity and appearance for decades without requiring replacement, refurbishment, or maintenance involving environmentally harmful coatings or chemicals.

The lighter weight of high-strength stainless steel structures reduces transportation energy requirements and can allow for less substantial foundations, further decreasing the overall environmental footprint of construction projects. This weight advantage becomes particularly significant in large-scale architectural applications where material volumes are substantial.

By eliminating the need for protective coatings that might contain volatile organic compounds or other environmentally problematic substances, high-strength stainless steel frames also contribute to healthier indoor and outdoor environments throughout their service life.

Maximizing design potential with high-strength stainless steel frames

High-strength stainless steel frames represent a revolutionary approach to structural design, combining superior mechanical properties with exceptional durability and sustainability. By understanding and leveraging these advantages, designers can create structures that are simultaneously more elegant, efficient, and environmentally responsible.

The significant weight reduction possible with high-strength stainless steel—up to 50% in some applications—translates directly into cost savings across material, transportation, and installation phases. These economic benefits complement the aesthetic advantages of more minimalist structural elements and longer unsupported spans.

Our manufacturing processes, utilizing both roll forming and press braking, enable precise dimensional control and consistent quality that designers can rely on. This manufacturing flexibility supports creative architectural expressions while maintaining structural integrity and performance reliability.

The sustainability benefits of high-strength stainless steel frames align perfectly with contemporary environmental priorities, reducing material consumption while providing structures that will perform flawlessly for decades with minimal maintenance requirements.

By choosing high-strength stainless steel hollow sections for frame design, architects and engineers gain access to an expanded palette of design possibilities without compromising on structural performance or long-term durability. This perfect balance of form and function represents the future of efficient, sustainable structural design.

This article was created with the help of AI and reviewed by a human. It may include mistakes.