“Together we create a safe work culture and build safety standards at our workplace, day by day.”

Safety first! We are focusing on safety work as our priority number one, tells Stalatube Sp.

Zo.o. Plant Manager Arkaniusz “Arek” Baran.

He has been running the factory for over six years now and highlights the importance of the safety culture among the whole team. Everyone is responsible for his own as well as his colleagues’ safety. Nevertheless, the challenge lies in the fact that daily routines tend to override caution. The factory’s motto is “Think twice before you do it”.

In the picture Mateusz Maćkowiak our Welding Supervisor. The Polish employees wear durable work clothes that increase safety and protect them from accidents.

Investments in modern machines and safety devices

Occupational safety was highly considered already from the beginning of the plant. The production facilities were planned for safety first – down to the smallest detail. Even the pathways were designed and painted with spot colours and warning signs. Most of Stalatube Poland’s machines are very modern and secure providing excellent safety work level.

“In the past, all our accidents happened with the older machines. We are trying to upgrade the rest of them to work more safely in the future,” ensures Arek.

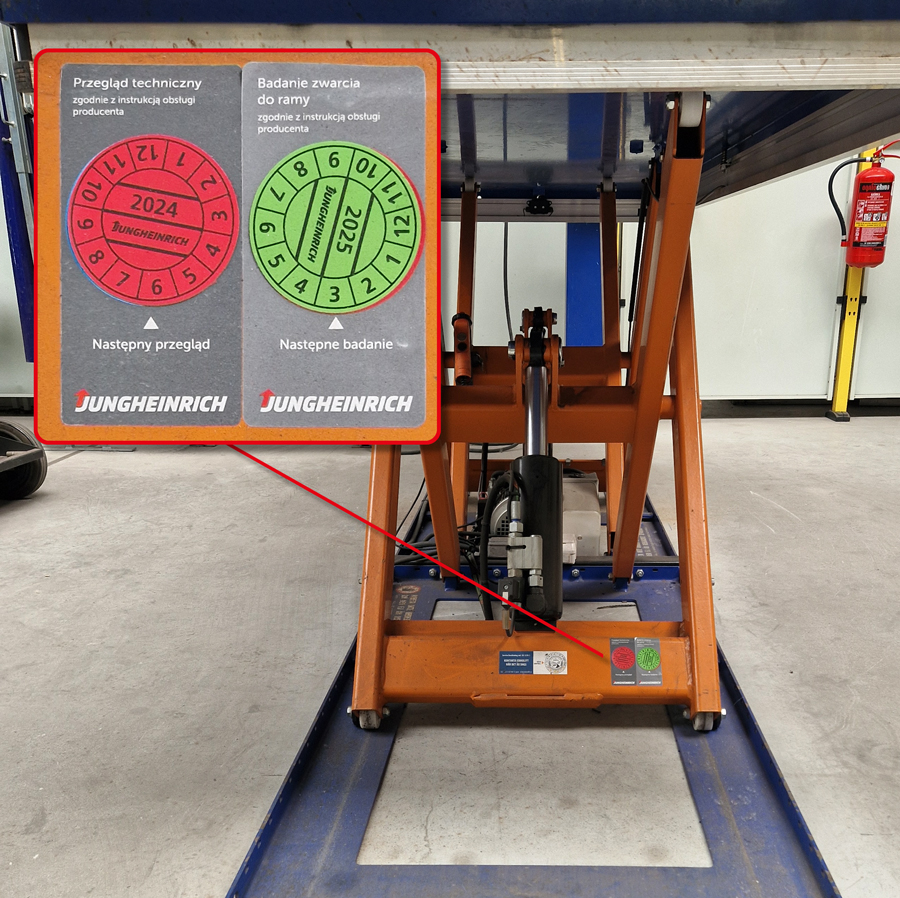

Polish employees prioritize maintaining the machines in optimal shape and condition as well as investing in additional automatic safety devices. As an example, the I-beam line will be upgraded according to the newest safety standards. The same safety investments have been already made with the saw and big roll-bending machine. Even small transport pallet forklifts, tables, and racks are supervised by outsourced service.

“We invest in the latest type of safety devices on our machines,” tells Arek.

Supporting devices are supervised together with local authorities and outsourced specialists.

All in all, the order at the workplace ensures safety. Places are kept clean from dirt and oil. So, let’s ask the operator Robert Maciejewski’s opinion on how 1000 accident-free days is achieved. He has been working at Stalatube almost five years. Robert’s expertise has been put to good use, for example in modifying a roll-folding machine.

“Our factory ensures employee safety by preventing work-related hazards through proper work organization, use of preventive measures, and by organizing appropriate employee training. There is excellent access to personal protective equipment and collective protection in the plant, thanks to excellent working conditions.”