Tanja Pakarinen our EQHS & Sustainability Engineer has written a blog post about circular economy. You can read it below.

Stalatube’s three ways to promote the circular economy

A circular economy is a resource-efficient economic system and environment in which production and consumption generate as little waste and wastage as possible, i.e. waste is minimized, and raw materials are used sustainably and efficiently. The circular economy exploits reuse and recycling for as long as possible, thereby reducing the consumption of natural resources.

The system aims to deliver economic performance and sustainable growth within the limits of environmental resilience. It differs from the current linear economic model, which uses virgin resources and products that end up as waste. Instead, the circular economy recycles existing materials instead of constantly producing more. Products and materials are not destroyed but reused over and over again to make new products. The circular economy is a continuous cycle that optimizes resource use and maximizes materials recovery. Ultimately, there is no waste.

The circular economy is also strongly based on life cycle thinking, where environmental considerations ensure the product’s overall environmental impact and identify the worst environmental impacts. At Stalatube, we have carried out life cycle modeling for our products and this information can be found in the EPDs.

We are determined to promote the circular economy:

1. By developing more sustainable products

We design products that are sustainable. i.e. they have a long-life cycle and are recyclable. A good example of this is the special tubes we have developed, whose mechanical properties mean that less raw material is needed to achieve the same strength class. By working with our customers to produce products that are precisely tailored to their needs, our cut-to-length service allows our products to be manufactured and installed at the customer’s site without additional waste. Steel, our main raw material, is 100% recyclable without any loss of quality.

2. Innovating new ways to increase resource efficiency

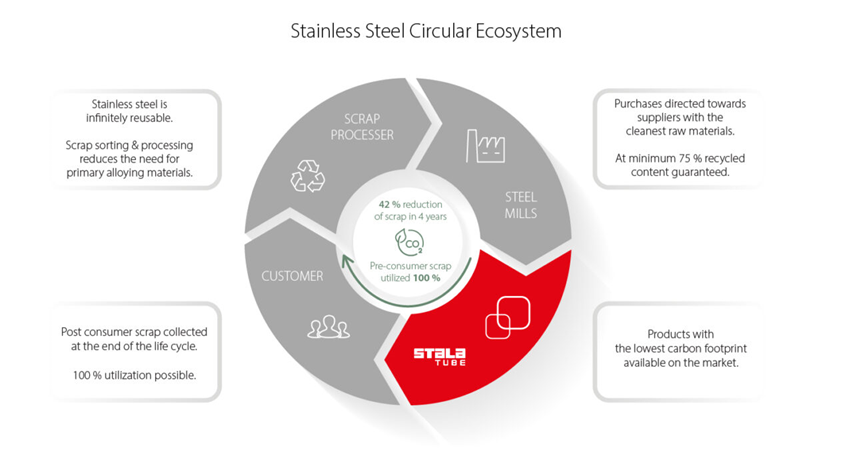

We minimize and recycle side streams and waste in the factory. Side streams from different grades of steel are efficiently recycled. 100% of other side streams or waste is either recycled or used for energy. Over the last five years, we have reduced the amount of scrap coming from production by 34.5% compared to production tonnes.

3. By increasing the proportion of recycled steel in the materials we purchase

We guarantee that at least 75% of the raw material we use in our manufacturing is recycled. We have a target to continuously increase this percentage. In some cases, the share of recycled raw material exceeds 90%.

In general, the idea of a circular economy is that products are designed to be sustainable, made from high-quality raw materials, and thus have the longest possible life cycle. Manufacturing is carried out with the lowest possible wastage rate, i.e. in a resource-efficient way, and at the end of its life cycle the material is recycled and eventually used to make new pipe. This is something we at Stalatube have achieved to perfection.

Although sustainable growth is at the heart of our business, the world around us is not ready: zero emissions will not be achieved in a day, a week, or even a month. Change will take time, but all in all, increasing and fully exploiting the circular economy would make it possible to tackle climate change, biodiversity loss and, in general, to end all pollution.