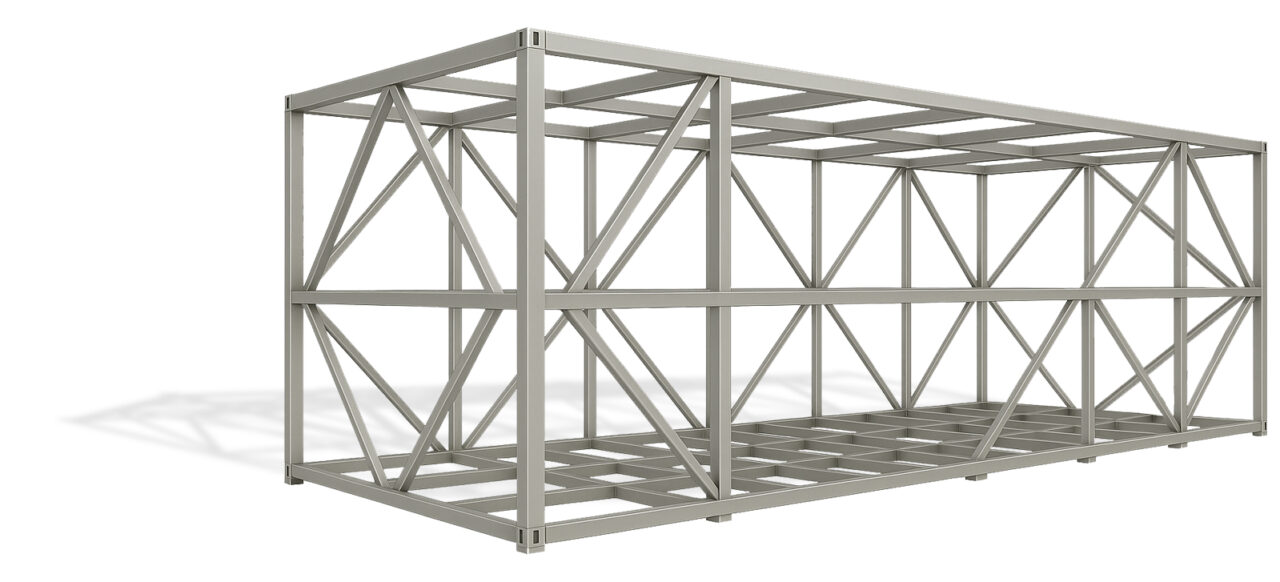

Multi-element gas containers (MEGCs) are essential in the transport of compressed gases such as hydrogen, helium, and natural gas. These containers are exposed to both mechanical and environmental stress, making the design and material selection for the supporting frame structure critically important.

One emerging solution is the use of high-strength stainless steel square and rectangular hollow sections in MEGC frames. Here’s why this material choice makes sense:

1. Excellent corrosion resistance, even during storage

MEGCs are exposed to medium to high corrosion environments during transport – think salt spray, industrial fumes, or road chemicals. But often overlooked is the corrosive exposure during storage: long idle periods in outdoor, industrial settings with high humidity or airborne pollutants.

High-grade stainless steels, particularly austenitic and duplex grades, offer long-term corrosion protection without additional coating. This significantly reduces maintenance needs and ensures better structural reliability over the lifecycle of the container.

2. Lighter weight = lower energy use and CO₂ emissions

MEGCs are mobile assets, and every kilogram counts. Using high-strength stainless allows designers to optimize wall thicknesses and reduce frame weight, translating directly into lower fuel consumption and lower CO₂ emissions during transportation.

What’s more, material efficiency also reduces emissions during manufacturing – less steel, fewer welds, and less energy consumed in fabrication.

3. Safety under impact, toughness matters

Accidents in transport or rough handling during terminal operations can cause structural damage. High-strength austenitic (f.ex. Stala500 / LN301) and duplex (F.ex. Stala630D) stainless steels combine superior strength with excellent toughness, which may help absorb impacts and reduce the risk of brittle fractures.

This characteristic deserves further study in the MEGC context, but it’s already clear that toughness under extreme conditions is a valuable design parameter for transport safety.

4. Potential to increase payload capacity

By reducing frame weight without compromising strength, stainless hollow sections may allow higher gas payloads within the same gross vehicle weight. This means better efficiency per trip, higher profitability, and a lower environmental footprint per unit of gas transported.

This potential should be evaluated case by case, but the benefits are clear when mass limits are a constraint.

5. Easier manufacturing, no need for hot-dip galvanizing

Due to the physical size of MEGC frames, hot-dip galvanizing is often difficult and expensive. Stainless steel provides a built-in corrosion barrier, eliminating the need for zinc coating and simplifying the production workflow – especially valuable for modular or globalized supply chains.

The writer

Tommi Purtilo

Business Development ManagerEnergy Industry, Hollow sections & profilesStalatube Oy (Finland)

Technical support