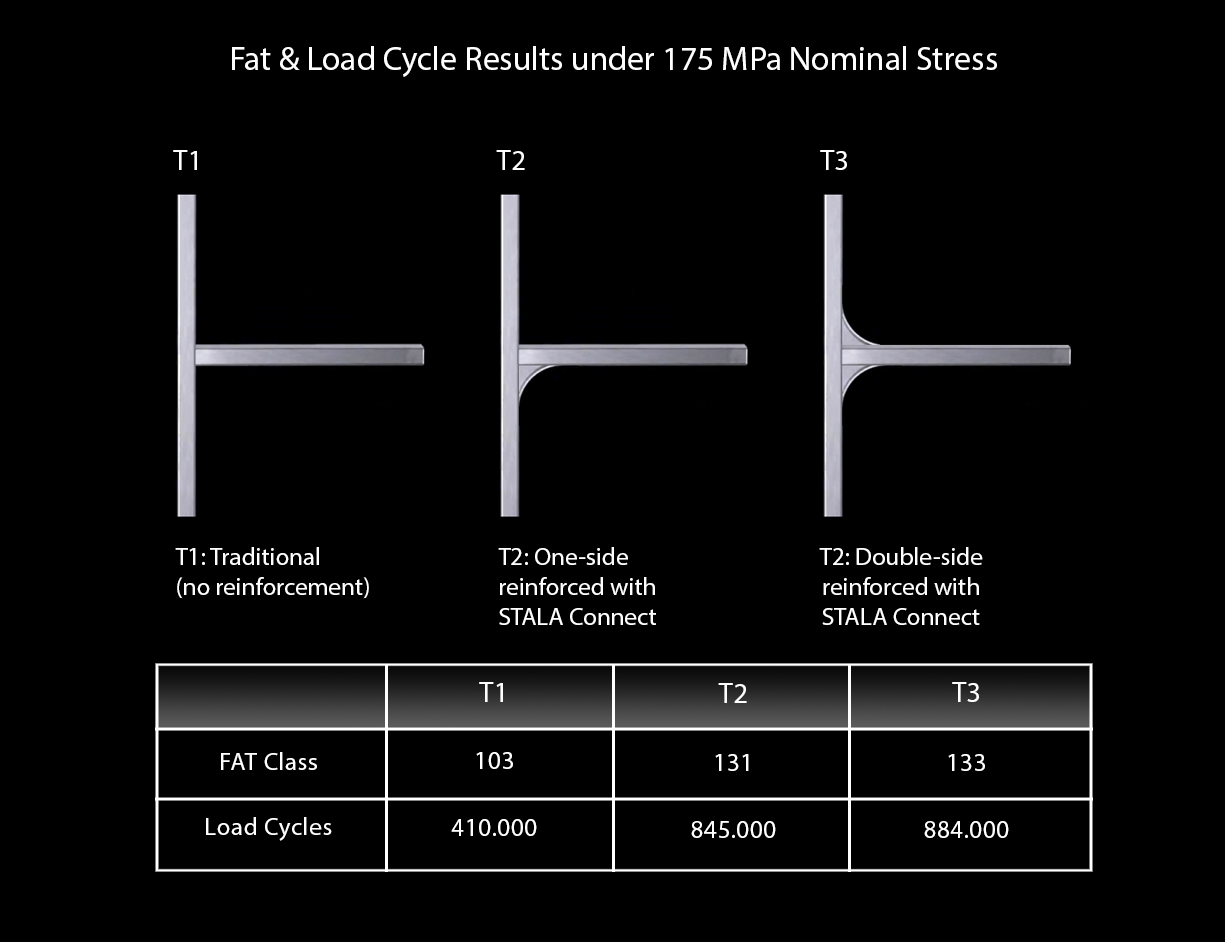

The STALA Connect press part is designed to improve the fatigue strength of welded tube connections. It can be used in L, and T joints to ensure smooth load transfer away from the joint. For L/T joints, it offers up to 30% better fatigue strength under bending loads compared to traditional joints.

The new press part solution for welded tube connections

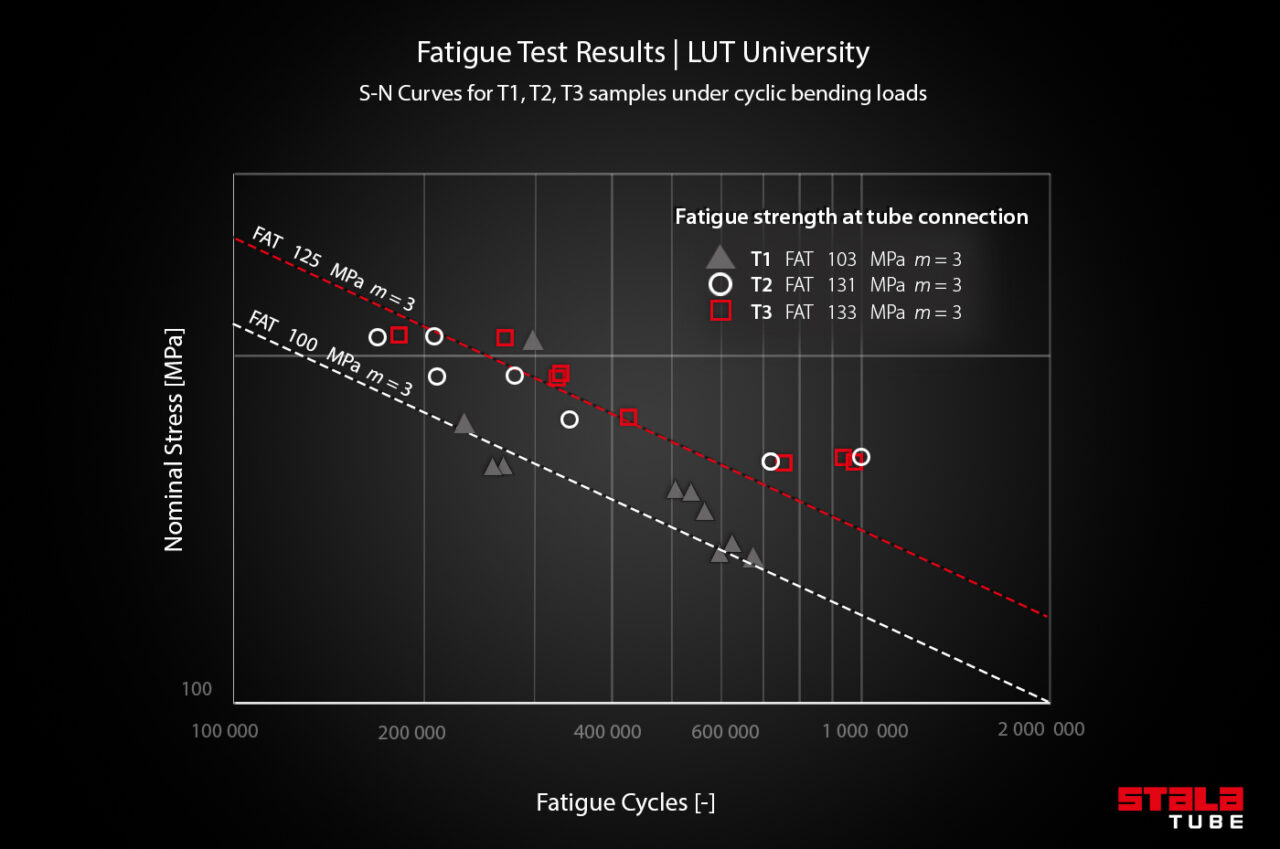

STALA Connect is our innovation for lightweight bus body structures where the bending fatigue strength of welded tube connections is critical. By utilizing STALA Connect press parts in L and T joints, you can achieve a 30% increase in the FAT class (Fatigue Assessment Technique) by doubling the bending fatigue life cycles. Combining STALA high-strength tubes with STALA Connect press parts allows you to optimize your bus structural design and potentially reduce the wall thickness of tube materials.

- Outer Radius 100 mm

- Width 40 / 50 mm or according to the customer request

30% increase in FAT class under bending loads