Stainless steel is, as we all know by now, a very sustainable material – and because of its amazing mechanical properties and light weight, Lean Duplex takes the sustainability of stainless steels to another level. In this blog I uncover the five unquestionable environmental benefits of this versatile material.

1. Lean Duplex is 100 % and endlessy recyclable

Like all stainless steel, Lean Duplex is a completely recyclable material. And not just once or twice – its mechanical properties do not alter or weaken even after countless rounds of recycle and reuse. As there’s no need for surface treatment, it’s also easier and safer to recycle than other metals. Coated materials must be recycled as hazardous waste, but stainless steel still has a positive waste value when the structure or building is dismantled.

Actually, the key problem using recycled stainless steel when making new stainless steel such as Leand Duplex is finding it – as a highly durable construction material, most of previously produced stainless steel in the world is still in use in buildings and structures.

2. Lean Duplex means no toxins or hazardous substances

Because of its chemical composition, Lean Duplex and Duplex steels are highly corrosion-resistant. This eliminates need for surface treatment which significantly reduces risks of polluting the environment. Also, for example in restorative construction, stainless steel is a more economical option because it does not react when it comes in contact with other materials – in the same circumstances many other metals will eventually or even easily corrode.

Besides of removing possible harms caused by external coating, the chemical composition ensures that Lean Duplex is a safe material for the workers of the construction site and the environment surrounding it.

No toxic or harmful substances are released into the air, soil or water.

There are no toxic or otherwise harmful substances released into the air or into the soil with the rain water as from many other raw materials. With stainless steel there is a chemical reaction that produces a passive coating onto the surface of the material – this prevents harmful substances getting into the air and rain water and ultimately soiling ground water – or in offshore structures, polluting the ocean.

3. Lean Duplex Stainless Steel has a very, very long life cycle.

Coated carbon steel lasts 15-20 years on the roof cover of a building, and maybe a bit longer in a bridge or other civil engineering construction. The life cycle of Duplex stainless steels is easily more than 50 years – as stainless steel endures well the humidity gathering under roofs and behind walls, in construction the thumb rule is that the life cycle of the material is as long as the building itself.

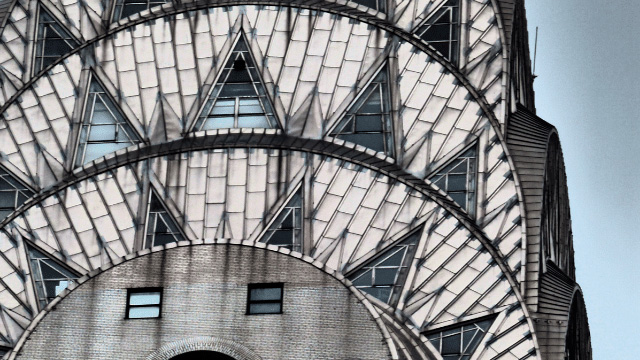

We can well use one of New York’s famous landmarks to exemplify this (even though Lean Duplex was not used as it was not yet invented): The Chrysler Building, one of the first large buildings in the world where a significant amount of stainless steel has been used, was built over 90 years ago, between 1929-32. Its architecturally distinctive spire was coated with 1.4301 stainless steel, which is still in excellent condition although it has been cleaned only once since its completion. Think how long a similar construction made with modern Lean Duplex, a much more advanced material, will stay in usable condition? Only time will tell, but I believe it must be well over 100 or even 200 years.

The Chrysler Building is considered one of the most beautiful skyscrapers in the world. The most striking part of the building is the art deco style stainless steel dome that reaches the height of 319 metres. The stainless steel structures and plates used to create the dome are visible in this picture.

4. Lean Duplex Stainless Steel is maintenance-free

Admittedly in the long run stainless steel too benefits from cleaning from time to time, but because of its chemical composition and non-corrosive nature, there is no need of protective coating as for example with carbon steel or aluminum. Imagine a long bridge or an offshore platform in the middle of the ocean, and what kind of resources – toxic paints, tools, work, transportation and energy – it takes to repaint their structures every five to ten years. With Duplex materials there’s no need for that at all!

Less maintenance also equals to increased safety. When the unnecessary but time- and energy consuming rounds of repainting are avoided, the workers are more protected from both the dangerous working environments and the exposure to harmful substances. Not to mention the previously discussed risks these toxins cause to the environment.

5. Lean Duplex is a lightweight material

Lean Duplex, as an optimal combination of austenitic and ferritic grains, has better mechanical properties than most metals and even standard stainless steel grades. Its increased strength, flexibility and toughness at different temperatures mean that the structure can be made of a much thinner material. This leads to significant weight savings of the structure, which creates multiple environmental benefits.

First of all, with Lean Duplex, less material is needed for the structural tubes to achieve the desired strength of the structure. And less material always equals to smaller carbon footprint of the finished product. With less material to work with, there is always less waste in the manufacturing process. The assembly (and ultimately dismantle at the end of the lifecycle) of the structure requires less energy when working with lighter construction elements.

Less material always equals to smaller carbon footprint of the finished product.

However, the biggest carbon footprint reduction of Lean Duplex is probably achieved in transportation. The transportation of the raw material to the tube mill, the finished tubes to a stockholder warehouse, and later to the construction site and finally the transportation of the dismantled tubes at the end of their lifecycle to a recycling facility – when all this is operated with 30 % less weight of the cargo, the reduction of the carbon footprint is obvious.

As the transportation distances are often long and the locations of many Lean Duplex projects (such as Offshore platforms) are remote, transports emissions and energy consumption can reach very high levels, and any reduction in those are crucial for the environment.