Use Stalatube’s expertise for your benefit to take a firm step forward to the future.

We want to help customers create the world’s most lightweight bus body while maintaining impact safety and fulfilling the requirement regulations with our superior stainless steel materials. This is done by choosing the right stainless steel grade and optimizing the structures and their dimensions. We want to help you to gain the most out of Stalatube’s product range and get the most out of stainless steels’ benefits. That is why we do not just offer you our stainless steel tubes and components but we also offer you the full service.

We believe in long-term customer relationships. We know that by optimizing the right Stalatube products with the optimal bus body solutions, we’ll achieve the most beneficial solutions for our customers. By using the right materials for the right positions we’ll gain the most benefits out of bus designs.

In practice, we offer you our expertise for your use – without any cost. Our purpose is to build up cooperation with our customers that lasts – just as we offer our roster free solutions which last forever.

Advantages of stainless steel for the transport industry

- Superior high strength material

- Lighter structures – up to 500 kg off the bus body weight

- Maintenance-free, low life cycle costs

- Price stability over time due to the low nickel content

- Superior corrosion resistance

- Tailored products reduce material waste

- 100 % recyclable, low environmental impact, smaller CO2 footprint

- Ready-to-assemble component kits

- Flexible stocking and delivery options

How to optimize a bus body?

There are many ways of optimizing the bus body and here are some examples on how exactly:

1. Using the existing design but reducing the thickness and cross-section of the tubes with high-strength stainless steel.

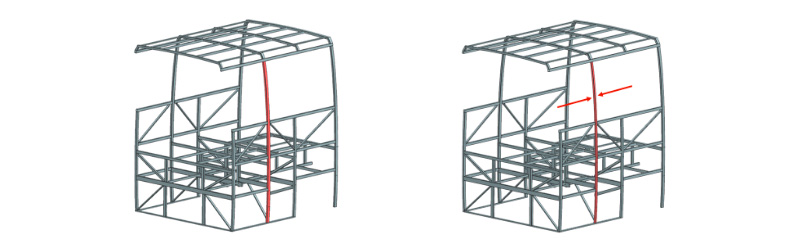

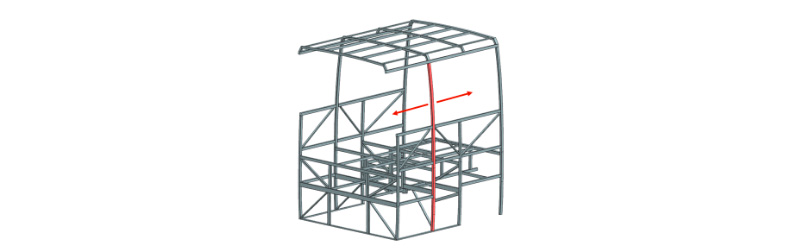

2. Adjusting the position of the tubes. This not only provides the advantage of weight reduction but also creates many possibilities in terms of design.

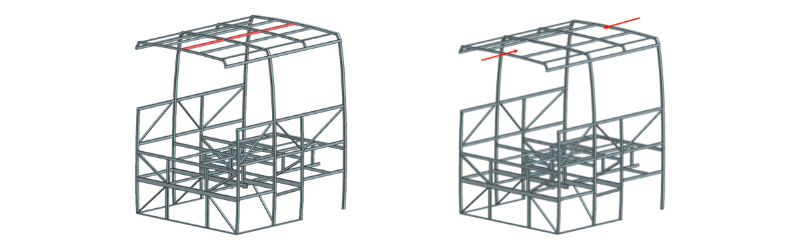

3. For a fully-optimized structure, designers can use our high-strength stainless steel to reduce the number of tubes in different regions.

Right material choice is the key factor

Designing the optimal bus body structure is like designing a puzzle; finding the right materials for the right places is essential. But do not worry, our team of experts is here to help you solve the puzzle. Stalatube offers a wide range of material options and our experts are here to ensure the optimal solution for your bus bodies.

How does our consultative process work?

Stalatube’s customer case process is based on cooperation and operative team work together with our customers. Every step of the way is determined carefully starting with customer expectations. We set up a common target and method used after the examination are made by Stalatube’s engineers. The final outcome will be simulated by using 3D programming. We also emphasize the importance of communication with our customers throughout the whole project.

Read more about what we have to offer for the transport industry.

Are you interested in the lightweight bus design consultation?

Our R&D Manager Mr. Emrah Dutkun is the backbone of our consultative design team. Emrah and his engineering team have a long experience in technical bus design and they are here to help our transport industry customers to choose the right materials and products for every unique project.

Over the past 50 years, we’ve gained expertise, created the world’s widest range of stainless steel hollow sections, and developed a global distribution network to be able to serve you in all corners of the globe, even in the most demanding projects and applications.

Please contact Mr. Emrah Dutkun for more detailed information: