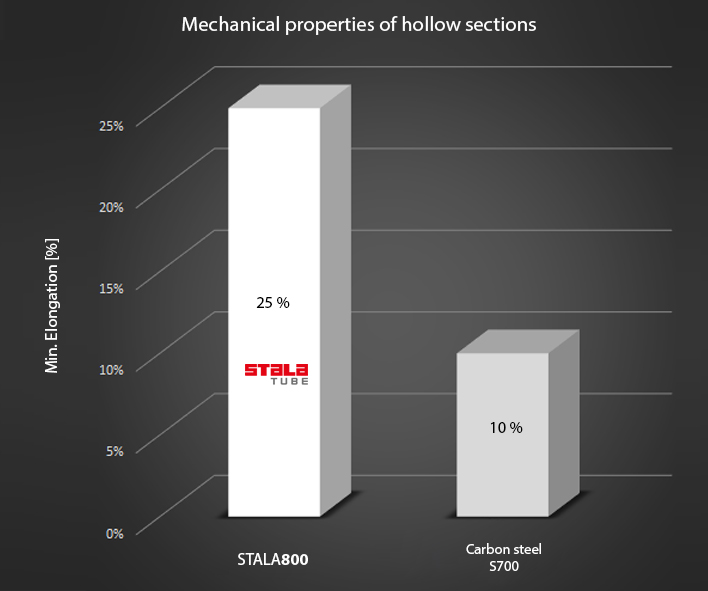

STALA800 (EN 1.4678) is a fully austenitic chromium-manganese alloyed steel which has exceptional combination of strength and toughness. It is designed to replace high-strength mild steel in demanding applications. The minimum yield strength of STALA800 hollow sections is 800 MPa and the minimum elongation is 25%. Due to the fully austenitic microstructure, it doesn’t suffer from embrittlement at low temperatures like many ferritic or martensitic steels does. This means that you don’t have to worry about the impact toughness of the material in any temperature. STALA800 can be also welded together with any stainless-steel or mild steel grade. Here we have the mechanical properties of STALA800 hollow sections, S700 mild steel was added for comparison.

The combination of high-strength and elongation gives STALA800 material exceptional energy absorption capacity which can be utilized for example in bus body structures to save weight of roll-over structures and collision guards where high-strength and energy absorption capacity is needed.

It has also much better corrosion resistance compared to mild steel, but we still recommend coating it to ensure sufficient corrosion resistance of the bus body.

The writer

Lari Brask

Director of Product Development and TechnologyStalatube Oy (Finland)

Technical support, Welding & materials