What industries commonly use recycled steel products?

Numerous sectors across the global economy have embraced recycled stainless steel as a cornerstone material for their operations and development. The versatility and durability of reclaimed stainless steel have made it indispensable in modern industrial applications. From massive infrastructure projects to precision manufacturing components, the adoption of recycled stainless material continues to grow exponentially. With sustainability becoming a priority for businesses worldwide, the repurposing of high-quality stainless steel has transformed from an environmental choice to a strategic business decision. At Stalatube, we’ve witnessed firsthand how various industries leverage our high-strength stainless steel solutions, particularly those made from recycled materials that maintain exceptional structural integrity while contributing to circular economy principles.

The manufacturing sector consistently ranks among the top consumers of recycled stainless steel, converting reclaimed materials into new products with minimal quality compromise. Energy production facilities—particularly renewable energy installations—rely heavily on durable recycled stainless components. Infrastructure development across urban centers increasingly specifies recycled stainless steel for its combination of longevity and environmental credentials. This material revolution spans multiple industries, all recognizing that sustainability and structural performance can indeed coexist.

How does the construction industry benefit from recycled stainless steel?

The construction sector has discovered numerous advantages from incorporating recycled stainless steel into modern building practices. Structural frameworks that utilize this material gain exceptional durability while simultaneously reducing the project’s environmental impact. Architects and engineers increasingly specify recycled stainless steel for critical support systems where reliability cannot be compromised. The material’s inherent corrosion resistance proves particularly valuable in environments with extreme weather conditions or high exposure to potentially damaging elements.

We at Stalatube provide high-strength stainless steel solutions that deliver superior load-bearing capacity for construction applications. Our structural profiles offer remarkable stability while significantly reducing overall structural weight compared to conventional materials. This weight reduction translates directly to cost savings in foundation requirements and faster installation times. Modern architectural elements featuring exposed stainless steel components particularly benefit from recycled materials, as they maintain aesthetic appeal without sacrificing structural integrity.

Building facades, support beams, and reinforcement systems all demonstrate enhanced performance when constructed from high-quality recycled stainless steel. The construction industry particularly values how these materials maintain their structural properties throughout their extended lifecycle, reducing maintenance requirements and associated costs over decades of service. For buildings designed with long-term sustainability goals, the implementation of recycled stainless steel solutions represents a significant step toward achieving certification under various green building standards.

Why is recycled stainless steel important in the transportation industry?

Transportation infrastructure faces unique challenges that recycled stainless steel addresses effectively. Shipbuilding operations increasingly incorporate recycled stainless components in areas exposed to harsh marine environments, where corrosion resistance becomes a mission-critical property. Railway infrastructure presents another sector where the durability of recycled stainless steel provides significant advantages, particularly in high-traffic zones and support structures. Commercial vehicle manufacturing has embraced these materials to enhance longevity while reducing overall weight, directly impacting operational efficiency.

Our lean duplex stainless steel (LDX) solutions offer transportation engineers a compelling combination of benefits. This high-performance material contributes significantly to weight reduction initiatives, which translate directly to improved fuel efficiency in various transportation applications. The structural integrity of properly manufactured stainless steel components remains consistent throughout years of service, even under challenging operational conditions that would compromise alternative materials.

Transportation terminals, bridges, and support infrastructure all benefit from the implementation of recycled stainless steel elements. These structures must withstand not only environmental stressors but also continuous vibration and loading cycles that would accelerate fatigue in lesser materials. By maintaining stability with relatively low weight, our stainless steel profiles allow transportation designers to create structures that balance performance requirements with economic and environmental considerations.

What sustainability benefits do industries gain from using recycled stainless steel?

The environmental advantages of utilizing recycled stainless steel extend far beyond simply reducing landfill waste. Manufacturing processes incorporating recycled content demonstrate significant reductions in carbon footprint compared to using exclusively virgin materials. Energy savings throughout the production cycle represent another substantial benefit, as reclaiming existing stainless steel requires considerably less energy than extracting and processing raw ore. This conservation of natural resources preserves valuable mining sites while reducing associated environmental disruption.

At Stalatube, we’ve committed to producing recycled stainless steel products that contribute meaningfully to our customers’ sustainability goals. Our manufacturing processes maximize resource efficiency while maintaining the superior structural performance that defines our brand. The stability under load that characterizes our products remains consistent whether using virgin or recycled materials, eliminating any performance compromise when choosing the more sustainable option.

Industries implementing recycled stainless steel components often qualify for various sustainability certifications and recognitions, enhancing their market position and stakeholder relationships. The impressive longevity of properly manufactured stainless steel products extends replacement cycles, further reducing lifetime environmental impact through decreased material consumption. This durability, combined with stainless steel’s infinite recyclability, creates a truly circular material solution that aligns perfectly with forward-thinking sustainability frameworks.

How is recycled stainless steel processed for structural applications?

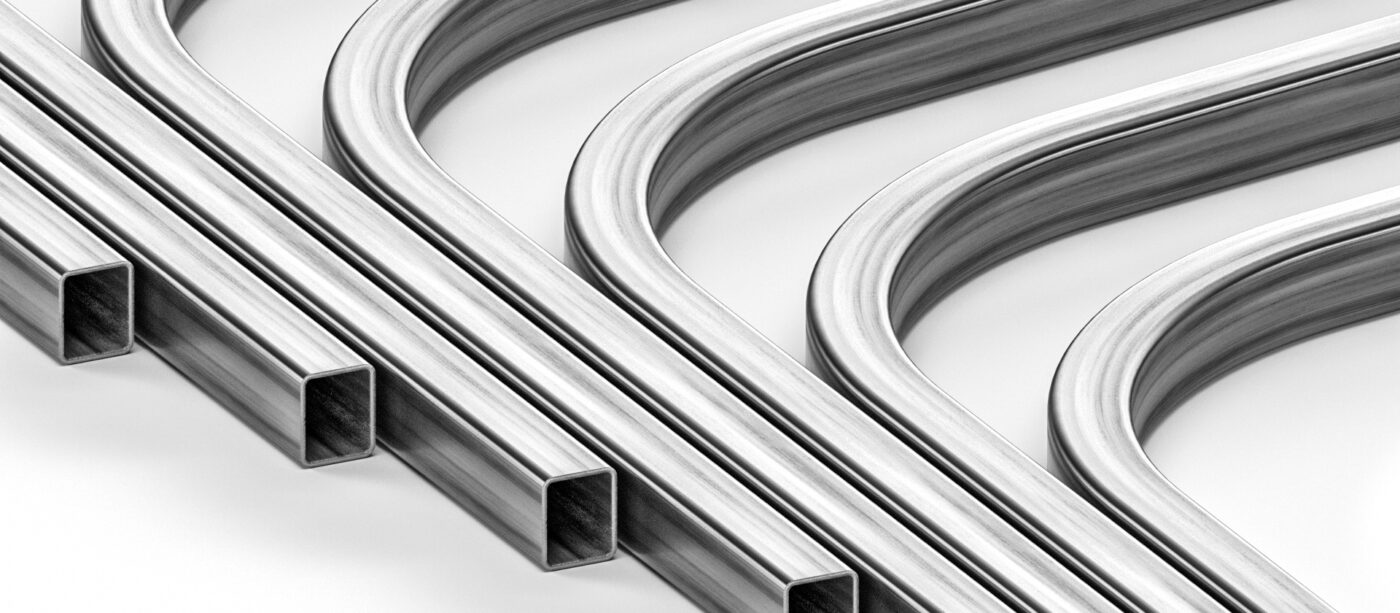

Converting recycled stainless steel into high-performance structural components involves sophisticated technical processes that preserve material integrity. The journey begins with careful sorting and processing of recycled material to ensure consistent composition and quality. Once prepared, the material undergoes either roll forming or press braking procedures to create precisely dimensioned structural tubes and profiles. These manufacturing methods enhance the material’s uniform strength distribution, a critical factor for structural applications where predictable performance under varying conditions is essential.

Our production facilities employ advanced techniques to ensure recycled stainless steel maintains optimal load-bearing capabilities. The manufacturing process carefully controls heating and cooling cycles to develop the ideal microstructure within the material. This attention to metallurgical detail ensures consistent performance throughout even the most complex structural components. Quality control measures verify dimensional accuracy and structural properties at multiple stages of the manufacturing process.

The resulting square and rectangular hollow sections provide uniform strength across all axes, offering significant advantages under compressive loads compared to alternative profile shapes. This structural consistency eliminates weak points that might otherwise compromise performance in critical applications. For specialized applications requiring custom specifications, our manufacturing flexibility accommodates modifications while maintaining the core structural benefits that define high-quality stainless steel structural elements.

Which industries require high-strength stainless steel structures?

Specialized sectors with demanding operational environments particularly value high-strength stainless steel structures. Offshore platforms face some of the most challenging conditions imaginable, requiring materials that resist corrosion from constant salt spray while maintaining exceptional strength-to-weight ratios under dynamic loading conditions. Heavy machinery manufacturing relies on structural components that withstand continuous vibration and mechanical stress without deformation or fatigue. Industrial equipment operating in demanding environments requires frames and supports that maintain dimensional stability despite exposure to temperature fluctuations, chemical processes, and mechanical forces.

We provide lean duplex stainless steel solutions that deliver optimal structural stability across all axes under compressive loads. This characteristic proves particularly valuable in applications where failure would result in significant operational disruption or safety concerns. The material maintains its mechanical properties across a wide temperature range, providing consistent performance regardless of environmental conditions. For industries where precision and reliability cannot be compromised, these attributes make recycled high-strength stainless steel an ideal structural material.

Chemical processing facilities benefit from the corrosion resistance combined with structural integrity that only high-quality stainless steel can provide. Food and pharmaceutical production environments require materials that maintain cleanliness standards while supporting heavy equipment and production lines. Even industries like renewable energy generation depend on durable structural components that withstand environmental exposure while supporting critical equipment. Across all these applications, the exceptional properties of properly manufactured stainless steel structures deliver the performance reliability that demanding industries require.